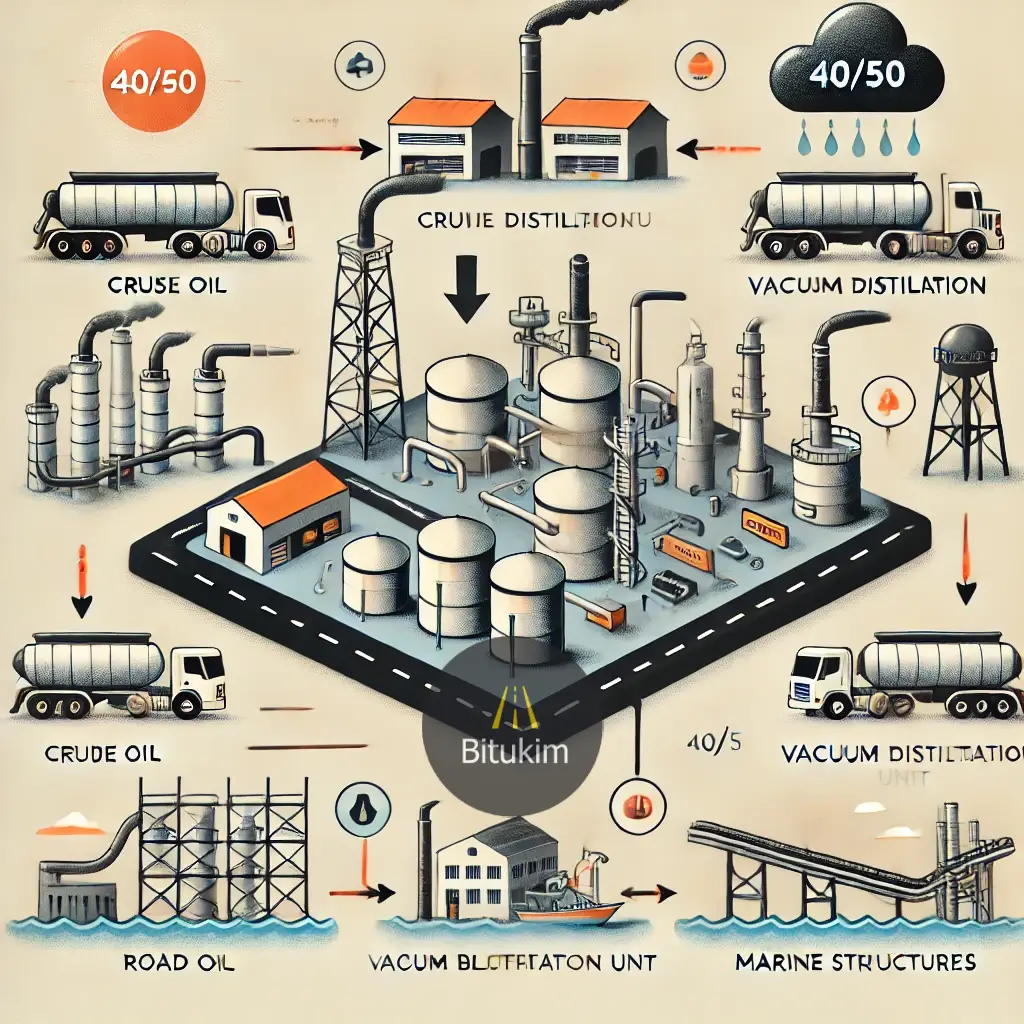

How Bitumen 40/50 is Produced

Production Process of Bitumen 40/50

- Crude Oil Distillation:

- Bitumen 40/50 is a by-product of the crude oil refining process. The production begins with the distillation of crude oil in a refinery.

- In this process, crude oil is heated to separate its components based on their boiling points. Lighter fractions like gasoline and diesel evaporate and are separated, while heavier residues remain at the bottom.

- Vacuum Distillation:

- The heavier residue left after atmospheric distillation is further processed in a vacuum distillation unit. This step reduces the pressure to lower the boiling point, allowing for the separation of heavier hydrocarbons.

- The bottom product of vacuum distillation is a residue known as vacuum residue, which contains a high concentration of bituminous materials.

- Blending and Air Blowing:

- To produce Bitumen 40/50, the vacuum residue may be further processed through air blowing. This involves blowing hot air through the bitumen at elevated temperatures (around 250-300°C or 482-572°F).

- Air blowing adjusts the physical properties of the bitumen, such as hardness and viscosity, to achieve the desired penetration grade (40/50). This process makes the bitumen more resistant to deformation and improves its durability.

- Quality Control and Testing:

- The final bitumen product undergoes rigorous testing to ensure it meets the specific penetration grade standards (40/50). Tests include measuring penetration depth, softening point, ductility, and solubility.

- Once the product meets the specifications, it is cooled and stored in tanks for further use or transportation.

Where Bitumen 40/50 is Used

- Road Construction:

- Pavement and Asphalt Concrete: Bitumen 40/50 is primarily used in hot mix asphalt for constructing and maintaining roads, highways, and runways. Its hardness and viscosity make it ideal for areas with heavy traffic loads and high temperatures.

- Base and Surface Layers: It is used in both base and surface layers of pavements to provide structural strength, durability, and resistance to weather conditions.

- Industrial Applications:

- Waterproofing: Bitumen 40/50 is also used in waterproofing applications, such as roofing materials, due to its adhesive and water-resistant properties.

- Insulation: Used in manufacturing insulating materials for building construction, pipelines, and other structures that require protection from moisture.

- Marine and Offshore Uses:

- Bitumen 40/50 is used in coating materials for offshore and marine structures, providing protection against saltwater corrosion and harsh environmental conditions.

- Manufacturing of Other Bitumen Products:

- Modified Bitumen: It serves as a base material for producing modified bitumen products, such as polymer-modified bitumen (PMB), which offer enhanced performance characteristics for specialized applications.

- Sealants and Adhesives:

- Utilized in producing various sealants and adhesives that are used in construction and infrastructure projects.

Key Benefits of Using Bitumen 40/50

- High Durability: Resistant to cracking, rutting, and deformation under heavy traffic loads.

- Good Adhesion: Provides excellent bonding with aggregates, reducing disintegration.

- Weather Resistant: Performs well under varying temperature conditions, from extreme heat to freezing cold.

- Versatile Applications: Suitable for a wide range of applications, from road construction to waterproofing and industrial uses.

Conclusion

Bitumen 40/50 is a versatile and widely used material in the construction and infrastructure industry. Its production involves multiple stages of crude oil distillation and refinement, resulting in a product with specific physical and chemical properties that make it suitable for heavy-duty road construction, waterproofing, and other industrial applications.