Gilsonite an Asphalt Modifier

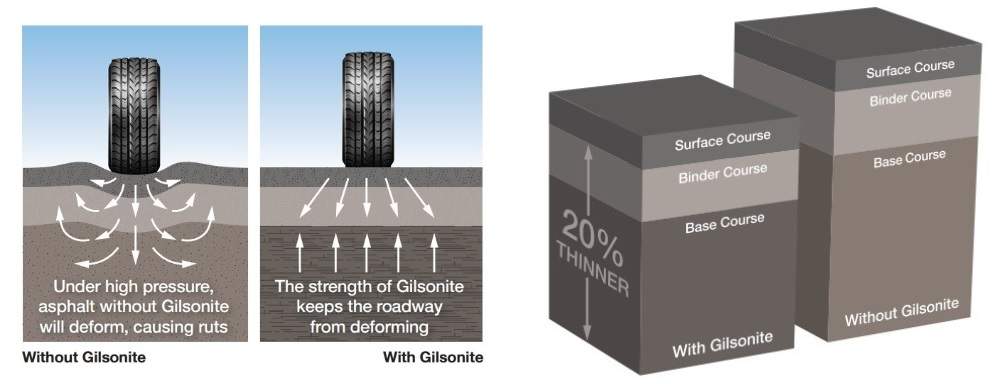

Gilsonite in asphalt industry is a naturally occurring solid hydrocarbon and is currently being marketed as an asphalt modifier. Powdered Gilsonite is added to asphalt paving mixes to improve pavement performance. Gilsonite is a modifier, which is intended to increase the stability of the pavement and help resist rutting often found on today’s pavements. Gilsonite is used as a performance-enhancing agent for asphalt mixes Bitumen modified paving mixes achieve higher PG grades (performance grade)and incorporate perfectly into the asphalt blend with no need for high shear milling as is the case with many other modifiers.

Gilsonite an asphalt modifier has higher stability, reduced deformation, reduced temperature susceptibility, and increased resistance to water stripping than non-modified asphalts. Gilsonite is also used to make both solvent-based and emulsion pavement sealers with superior appearance and weathering.

Powdered Gilsonite is added to asphalt paving mixes to improve pavement performance. High-performance road surfaces have long been made possible with the use of Gilsonite. Gilsonite s superior properties make it the go-to modifier for hot mix pavements and pavement sealers. Gilsonite is used in asphalt mix as an agent for increasing efficiency and productivity. The asphalt is mixed with the high content of Gilsonite without adding any other balancing materials so that it becomes a highly solid material.

Gilsonite as a modifier in a total of or portion regarding value and cost can replace SBS polymers in asphalt modifiers. Asphalts modified by Gilsonite have higher stability, lower shape changes, stability against low temperatures, and higher resistance against water compared to asphalts void of Gilsonite. In fact, the main task of Gilsonite in this application is to improve the stability of pavements and their resistance against shape changes which increases the ability to withstand high applied load and it is used in areas under high pressure.

There are almost 35 different replacements for Gilsonite, but since their ratios of cost to benefit are higher than Gilsonite’s, Gilsonite is more often used.

As an asphalt binder modifier, the unique properties of Gilsonite make a road that is less susceptible to high-temperature and deformation performance issues. When these modified binders are used in recycled asphalt pavements, Gilsonite adds back what time has taken from the old asphalt, making it easier to use more of this recycled material. The Gilsonite-modified asphalt binder will produce a stronger road that can be thinner by nearly 20 percent compared with other pavements.

Advantages Of Gilsonite Asphalt In Industry

- High strength and durability

- Superior deformation performance

- Reduced pavement thickness

- Reduced temperature susceptibility

- Increased resistance to water stripping

- Improved the economic performance of the road

- Improved resistance to fatigue

- Compensation for poor mixed design

- Compensation for poor aggregates

Gilsonite has been the subject of exhaustive study to improve characteristics for use in paving. Various properties of asphalt are manipulated to produce a product that has the appropriate wear properties, rut resistance, fatigue and low temperature cracking resistance, adhesion strength, viscosity and pour point. Rut resistance is resistance to longitudinal surface depressions in the wheel paths. Adhesion strength is the maximum adhesion strength of the joint sealant and the joint reservoir, including but not limited to, between the aggregate and the binder.

Properties such as durability and moisture resistance of asphalt concrete significantly improve pavement service life. When siliceous aggregate is used, then preventing moisture damage and stripping become distinctly required. Typically, stripping could be prevented by either using antistripping agents or by modifying the binders. The anti-stripping agent achieves its purpose by changing the aggregates’ affinity for water by changing the zeta potential (promote bitumen adsorption due to negative surface charge).

On the other hand, modifications of binders promote interface bonding between aggregate particles and bitumen. However, the process of applying anti-stripping agents or adhesion promoters is typically costly and, in some cases, may negatively impact other performance characteristics of pavement. Accordingly, we examine the merit of applying natural bitumen (gilsonite) instead of typically used anti-stripping chemicals in order to both promote resistance to moisture damage and reduce construction costs in asphalt.

In addition to being quite low-cost, Gilsonite has a chemical composition nearly similar to that of petroleum-based asphalt which makes it very compatible with asphalt binder.

Gilsonite acts as an enhancement to the quality of the asphalt mix, the presence of sulfur compounds in Gilsonite has an effect of asphalt resistance. Modified asphalt by Gilsonite is stronger, more tight, more adhesive, and easily mixed with asphalt without the need for high roller strength, In contrast to other modifiers, is mixed.

Gilsonite Additives for Concrete Construction

Gilsonite is used as a new additive to enhance the strength of concrete structures. Gilsonite’s unique features increase the process of production because Gilsonite is essentially water-proof and increases the process of water separation. When the concrete layers are formed due to pressure and temperature rise, Gilsonite makes the components of the concrete better tied to each other and the concrete is even stronger.

Benefits of gilsonite in Asphalt industry:

- Create a waterproof concrete floor

- Create a better bond to create more concrete strength

- Increased waterproofing up to 98%

In order to add Gilsonite to concrete, a special grade of high-quality powder of Gilsonite should be added to the concrete slurry in a concrete mixer machine to enhance the quality and integrity of the concrete.

Gilsonite in Pavement Sealers

Gilsonite’s proven properties make high-performance solvent-based and emulsion pavement sealers dry quicker, look better and last longer. As a natural antioxidant, it allows pavement sealers to stay blacker longer. Gilsonite’s unique molecular fractions rejuvenate the pavement being sealed. The strong bonding properties of Gilsonite help weatherproof the sealer.

- Natural antioxidant

- Rejuvenates pavement

- Excellent bonding properties

- Superior appearance and weathering properties

Making longer-lasting pavement helps the environment. By rejuvenating pavements with recycled asphalt instead of replacing them, there is a proven significant reduction in energy used as well as a reduction in required resources.

Gilsonite in Asphalt industry

Packing of Natural Bitumen Lump and Powder Micronized form

- Gilsonite in lump form like rock packed in the 500~1000 kg jumbo bag

- Gilsonite 200 mesh packed in the 500~1000 kg jumbo bag

- Gilsonite 300 mesh packed in the 500~1000 kg jumbo bag

- Gilsonite 30-40 mesh packed in the 500~1000 kg jumbo bag

- Gilsonite 100 mesh packed in the 500~1000 kg jumbo bag

- Gilsonite 300 mesh packed in the 25 kg pp bag

- Gilsonite 200 mesh packed 25 kg multi-paper bag

- Gilsonite 200 mesh packed 50 lbs multi-paper bag

- Gilsonite 30-40 mesh packed pp bag on pallet

- Gilsonite Bulk on the vessel

Analysis of Gilsonite in Asphalt industry

| NO | TEST | RESULT | TEST METHOD |

|---|---|---|---|

| 1 | ASH CONTENT,WT% | 5 | ASTM-D3174 |

| 2 | MOISTURE CONTENT,WT | 1 % | ASTM-D3173 |

| 3 | VOLATILE MATTER,WT% | 63 | ASTM-D3175 |

| 4 | SOLUBILITY IS CS2,WT% | 81 | ASTM-D4 |

| 5 | SPECIFIC GRAVITY @25C | 1.11 | ASTM-D3289 |

| 6 | NORMAL NEPTHAN INSOLUBLES,WT% | 79 | ASTM-D3279 |

| 7 | COLOR IS MASS | BLACK | - |

| 8 | COLOR IN STREAK OR POWDER | BLACK | - |

| 9 | SOFTENING POINT,C | 175 | ASTM-D36 |

| 10 | PENETRATION @25C | 0 | ASTM-D5 |

ELEMENT ANALYSIS

| NO | TEST | RESULT | TEST METHOD |

|---|---|---|---|

| 1 | CARBON,WT% | 84 | ASTM-D5291 |

| 2 | HYDROGEN,WT% | 7.1 | ASTM-D5291 |

| 3 | NITROGEN,WT% | 3.67 | ASTM-D5291 |

| 4 | OXYGEN,WT% | 3.1 | ASTM-D5291 |

| 5 | SULPHURE,WT% | 4 | LEGO(S)ANALYSER |