What’s Cationic Bitumen Emulsion?

Cationic Bitumen Emulsion is an aqueous form of bitumen where tiny droplets of bitumen are dispersed in water through the assistance of cationic (positively charged) emulsifying agents. The special characteristic of this product is that it can be utilized at lower temperatures without the need for heating, which conserves energy. The positive charge of the bitumen particles allows them to stick better to the negatively charged aggregate surface, especially under dusty or humid conditions. This makes cationic emulsions the best suit for the demands of modern road construction and maintenance.

Why Use Cationic Bitumen Emulsion?

There are numerous reasons why cationic bitumen emulsions need to be utilized in roadworks. For one, they are environmentally friendly with their cold application, which reduces fuel usage and emissions. Two, they have excellent adhesion on dusty or damp surfaces, meaning there is a stronger and longer-lasting bond between layers. Their fast setting time also means they are ideal for time-sensitive jobs and high-traffic roads. Plus, cationic emulsions are easier to handle, more transport-friendly, and are generally more cost-effective than hot mix binders — a smart choice for both performance and budget.

Typical Types

Cationic emulsions are categorized based on their setting speed and curing time once applied.

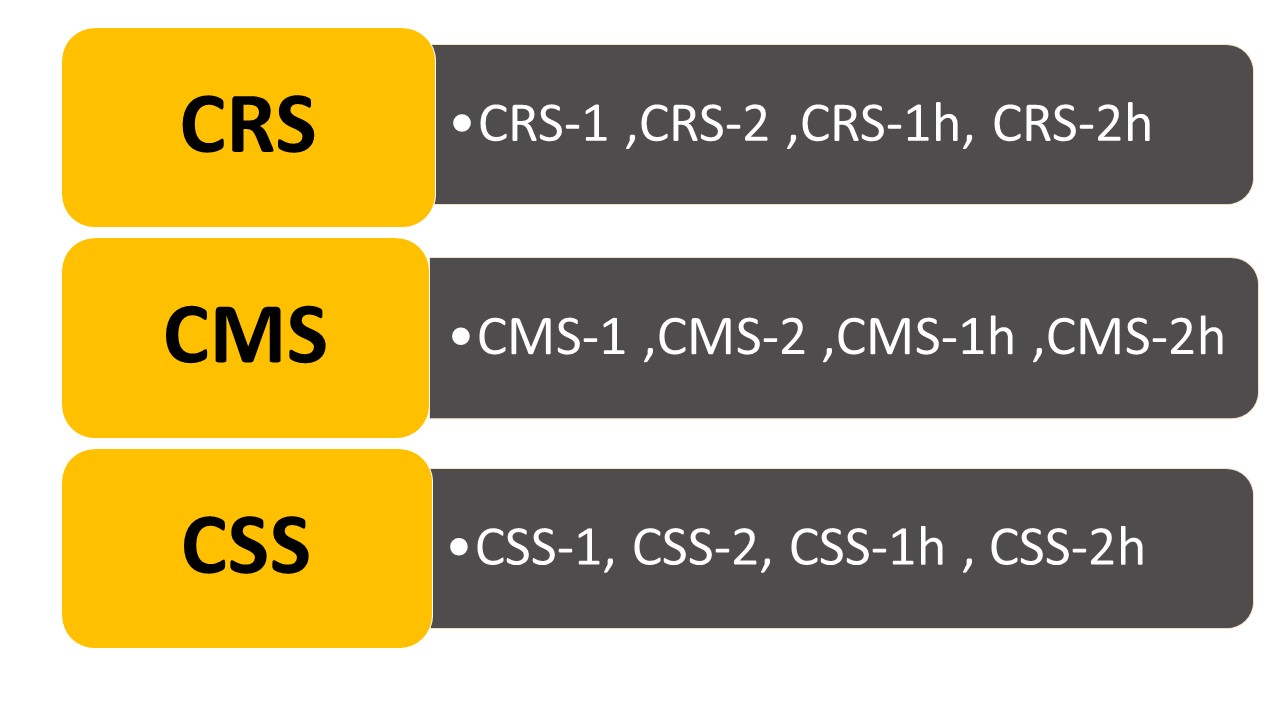

The three most common types are Rapid Setting (RS), Medium Setting (MS), and Slow Setting (SS).

RS emulsions are used in surface dressing and chip sealing; MS types are best for cold mix asphalt and patching repairs; and SS emulsions are ideal for prime coats and fog sealing.

The right choice is the secret to the success and longevity of the road treatment.

Applications

Cationic Bitumen Emulsion is extremely versatile and plays key roles in various stages of road construction and maintenance. It finds application in the manufacture of cold mix asphalt, surface sealing, dust suppression, pothole filling, tack-based coats (adhesion layers between asphalts), and prime coats over unbound surfaces. Its adaptability to climatic conditions, aggregate types, and project requirements makes it an efficient solution for use in projects from rural roads to large highway networks.

Require high-performance Cationic Bitumen Emulsion?

If you require high-grade cationic bitumen emulsions tailored to your project and climatic conditions, we’ve got you covered. Our products are built for durability, workability, and high adhesion — first-rate performance from the ground up. Reach out to us for samples, technical guidance, or custom formulation. Let’s build stronger roads together.